Laboratory

Maintaining and developing products quality, and having various parts to be used at wire tree, EKS set up a well equipped laboratory to test the products and raw materials of wire tree and directional signal lever. This laboratory is one of most reliable and well equipped centers for quality test of wire tree and directional signal lever in the country having most advanced equipments for dimension, temperature, mechanics, electronics and chemical plans and several technical and specialized team and enabled the company to manufacture specific equipments for operational tests and stability of the products based on standards. Some of these activities read as follows:

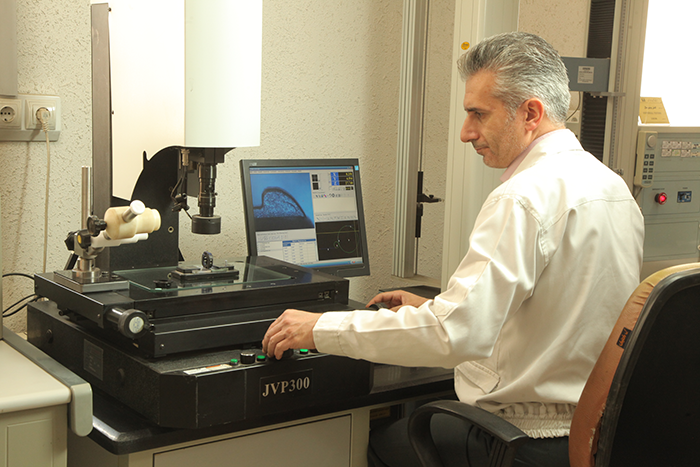

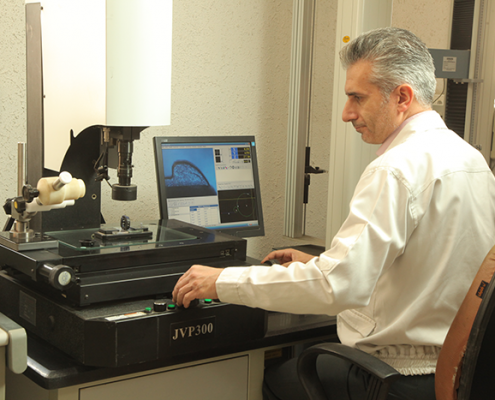

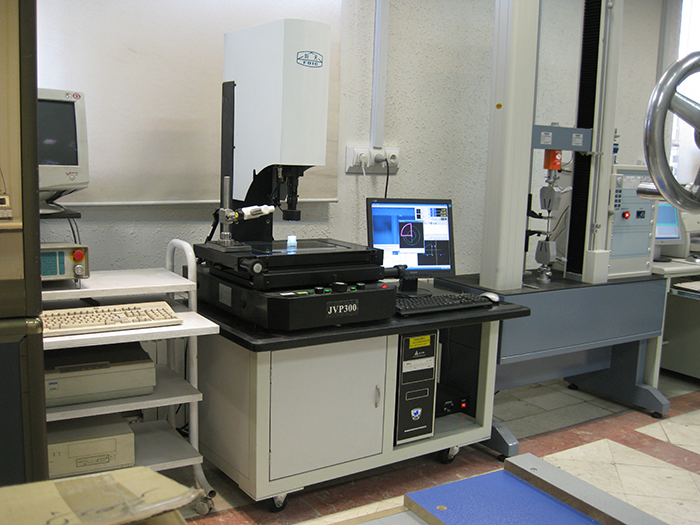

- Measuring parts dimensions by having a look and taking picture from part surface up to 280 times magnification to conformity with plan part and reverse engineering

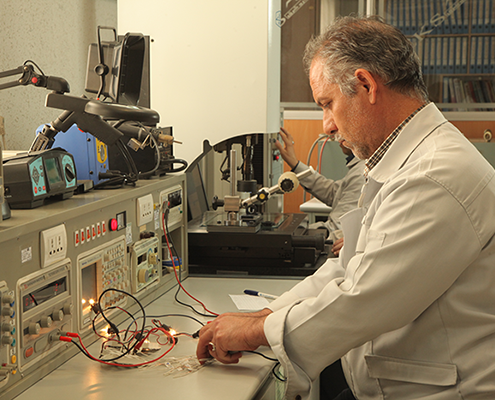

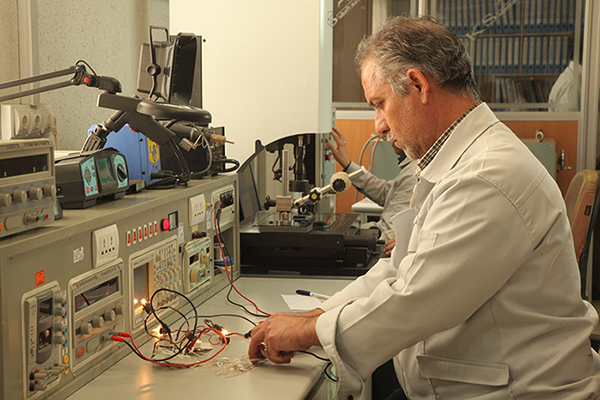

- Measuring voltage shortage, leakage flow and electric resistance of plastic sockets and insulators and diode conduct threshold, dielectric hardness test, anti-sparkling test for insulators and coatings

- Age test and investigation of part resistance and ware tree coatings against coldness, heat, and weather conditions

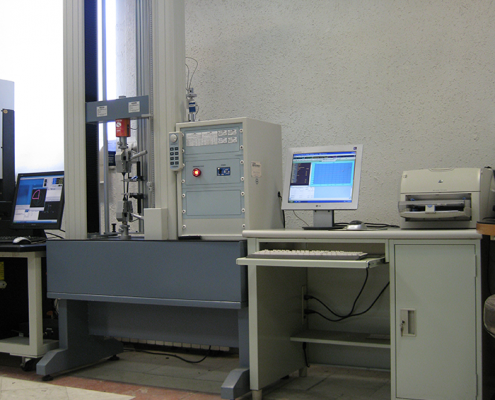

- Compute tear force and length increase on plastic and rubber parts (polymer base), assembling and un-assembling forces for sockets, terminals, dusters and directional signal levers

- Falling down test simulates the impacts of impacts of crash (rock, metal parts and etc.) regarding dimensions, positions of parts through clamp and jaw

- Wire scratch and friction test simulates the conditions of scratching and friction of wire to wire insulators or metal edge beside insulator

- corrosion and rust test for metals